| Sign In | Join Free | My wpc-board.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My wpc-board.com |

|

Brand Name : Hengcheng

Model Number : HVM2500 HVM2800 HVM3400 HVM4200 HVM4500 HVM4800 HVM5100 HVM5600

Certification : ISO Patent Certificate High-Tech Product Certificate

Place of Origin : CHINA

MOQ : 1 set

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 5 sets/month

Delivery Time : 60 days

Packaging Details : Standard shipping packaging

Equipment type : Vertical Mill

Applicable materials : gypsum (natural gypsum, desulfurization gypsum, phosphogypsum, etc.)

Feed particle size : ≤ 50 mm

Finished product fineness : 80-325 mesh (adjustable)

Features : Efficient, energy-saving, environmentally friendly

Output Size : 150-3000mesh

Power : 18.5-45KW

Product Name : Gypsum Grinding Mill

Dimension(L*W*H) : Depending on capacity

Core Components : PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Vertical Mill for Gypsum - High Efficiency Grinding for Construction Materials

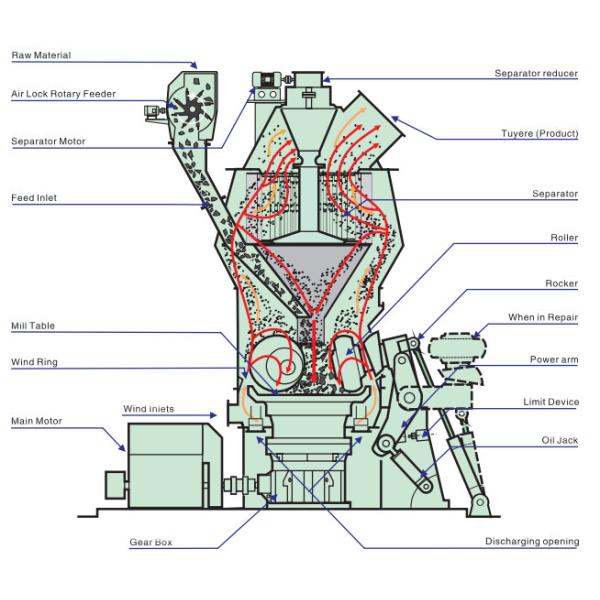

Operational Principle

The electric motor drives the grinding plate to rotate through a reducer, and the material falls into the center of the grinding plate from the feed inlet, while hot air enters the grinding chamber from the air inlet. Under the action of centrifugal force, the material moves towards the edge of the grinding disc and is crushed by the grinding roller when passing through the circular groove on the grinding disc. The crushed material is carried up by the high-speed airflow at the edge of the grinding disc, and large particles directly fall onto the grinding disc for re grinding. When the material in the airflow passes through the dynamic and static separator, under the action of the rotating rotor, the coarse powder falls onto the grinding disc for re grinding, and qualified fine powder is discharged with the airflow, Collect in the powder collection device, which is the product. Materials containing moisture are dried during contact with hot gases to achieve the required product moisture.

Specifications And Technical Parameters Of HVM Gypsum Vertical Mill

| Model | HVM2500 | HVM2800 | HVM3400 | HVM3700 | HVM4200 | HVM4500 | HVM4800 | HVM5100 | HVM5600 |

| Grinding Table Median Diameter(mm) | 2500 | 2800 | 3400 | 3700 | 4200 | 4500 | 4800 | 5100 | 5600 |

| Capacity(t/h) | 85-100 | 130-160 | 190-240 | 240-300 | 320-400 | 400-500 | 440-550 | 550-670 | 600-730 |

| Raw Material Moisture | <10% | ||||||||

| Raw Meal Fineness | R0.08<12% | R0.08<14% | |||||||

| Raw Meal Moistrue | ≤1% | ||||||||

| Main Motor Power(kW) | 800/900 | 1120/1250 | 1800/2000 | 2500/2800 | 3150/3350 | 3800/4200 | 4200/4500 | 5000/5400 | 5600/6000 |

| Illustrate | Re:Raw materials bond index≤13kWh/t | ||||||||

|

|

Vertical Mill for Gypsum - High Efficiency Grinding for Construction Materials Images |